Optimizing Orders with AI

Discipline:

Collaborators:

MySpot Shipper is a browser application that connects companies to carriers, allowing companies to book freight so they can ship their products. MySpot Shipper was released as a minimum viable product, and since then has added more functionality, while onboarding businesses. As larger companies have started to use MySpot Shipper, there has been a need to make larger quantities of shipments more streamlined/automated.

User Stories

I work for a large company that has to ship our products around the country. Booking a large amount of these shipments is time consuming, especially when you have to watch cost and there's deadlines to meet. Often time there's an overlap of shipments where they share stops

The Challenge

Work with the MySpot Shipper product owner and the data team to optimize large amounts of orders into as few shipments as possible, saving users freight cost.

Before

A company has products they need to ship, to and from multiple locations.

Company uses our TMS to create individual orders that need to be shipped.

For each shipment, users then select from a list of available carriers.

With AI

User still enters orders, but AI consolidates them into fewer shipments.

Now there are fewer shipments going out, saving companies money on freight.

The Approach

The approach began with conversations with the product owner, who had years of valuable logistics experience. Some of the main takeaways from those conversations:

- Most use cases involve optimizing anywhere between 10-50 orders.

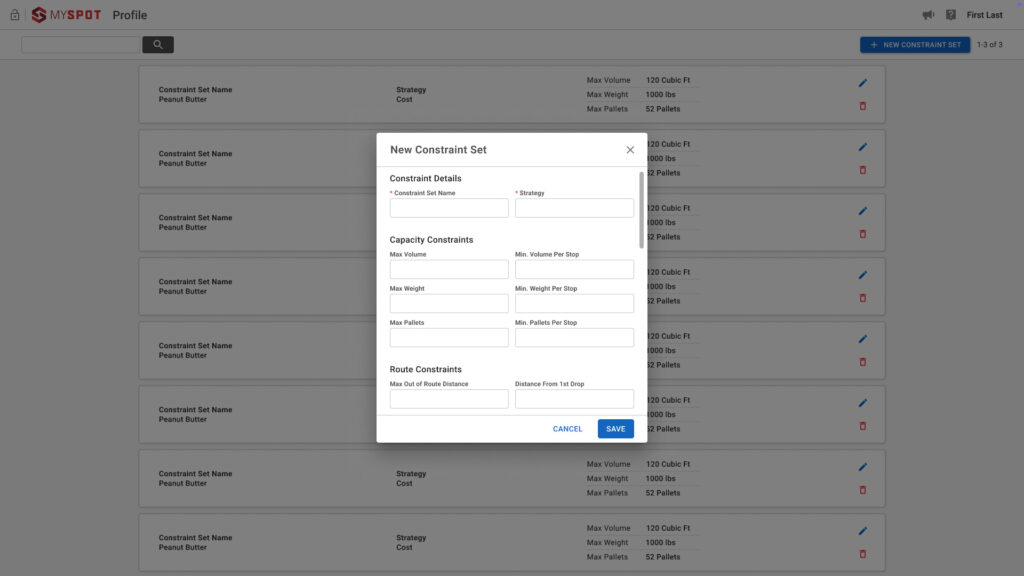

- Users will need the ability to set constraints when optimizing.

- After the AI has optimized shipments, users need the ability to make edits before finalizing.

The Solution

Maybe talk about different layouts or process

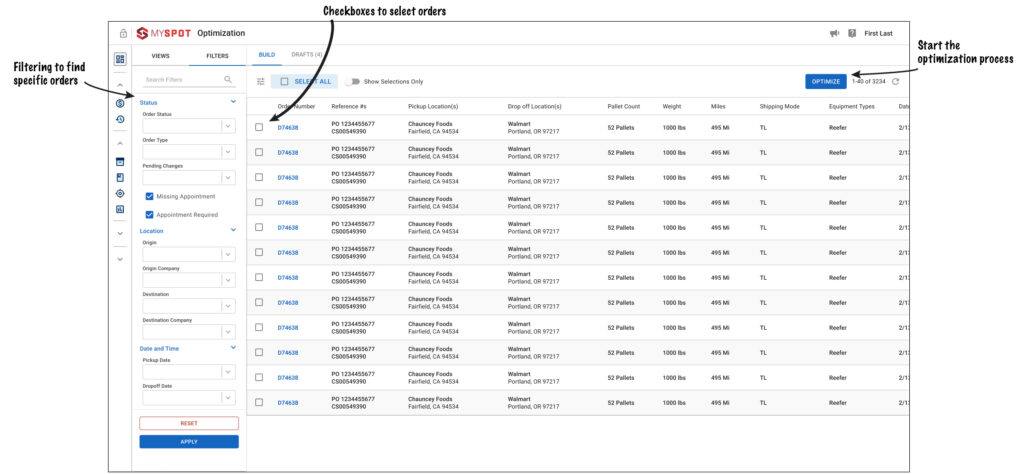

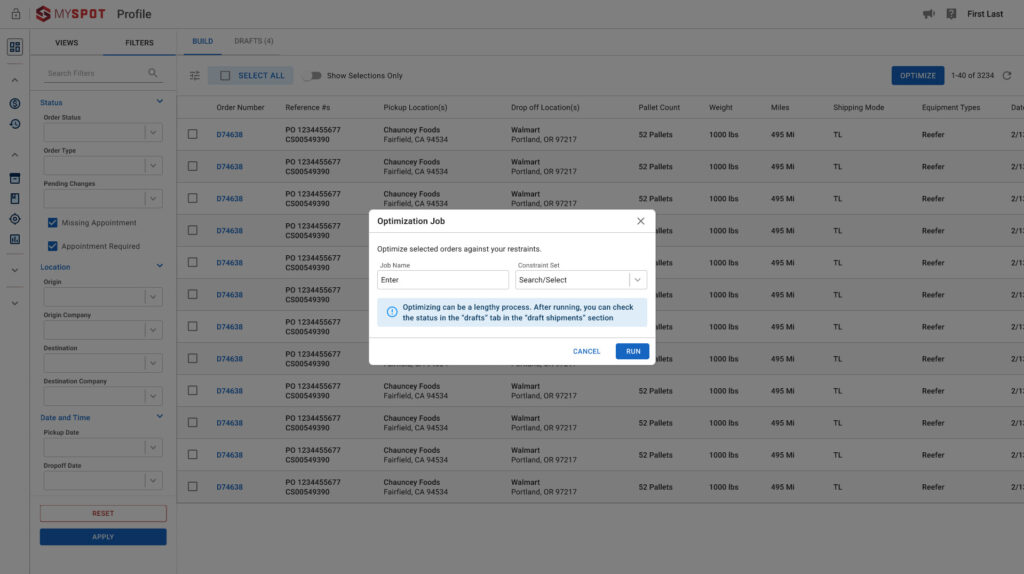

After orders are put in, the optimization process starts with selecting orders to optimize. Users can use the filtering options on the left to find orders.

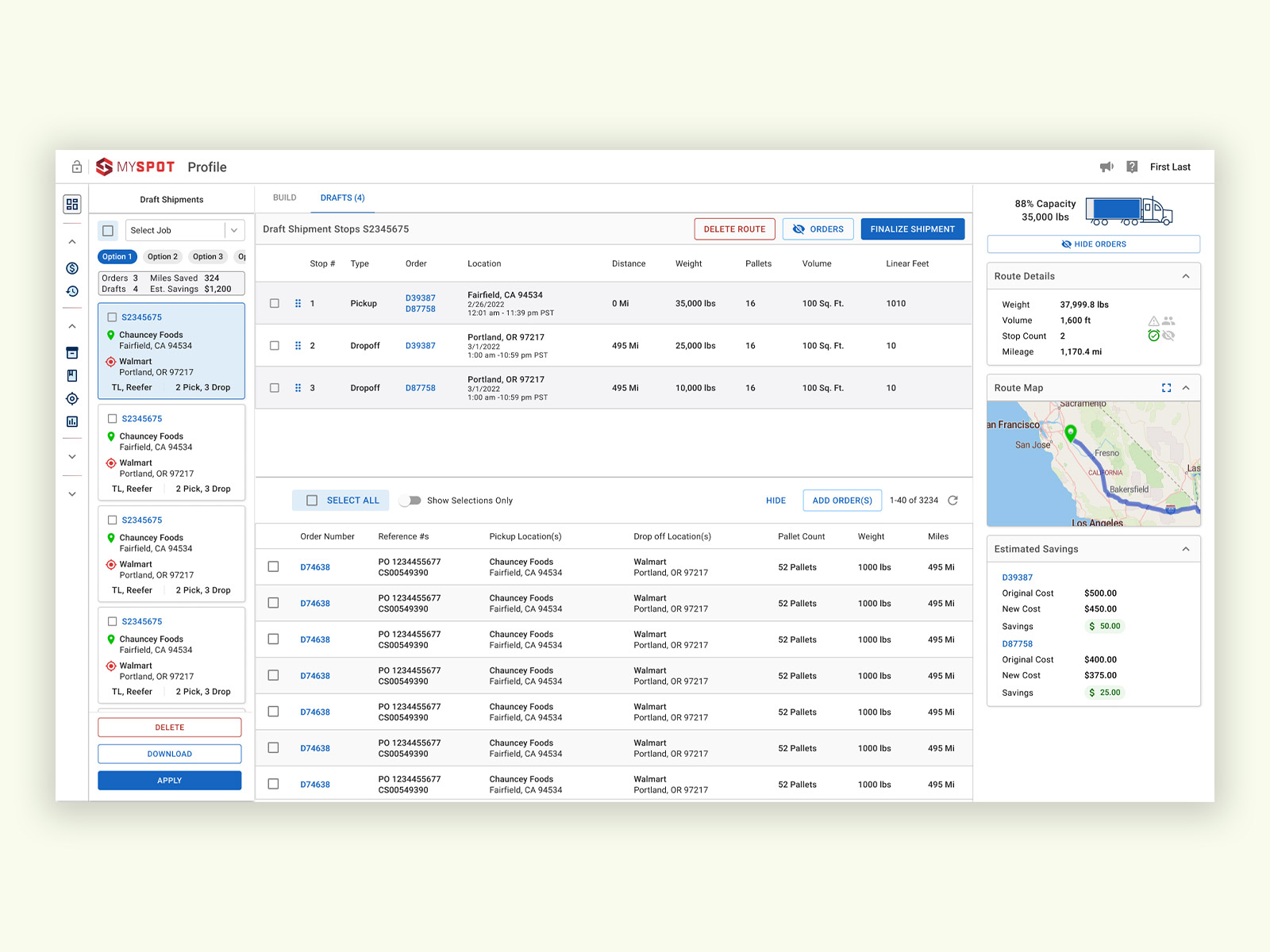

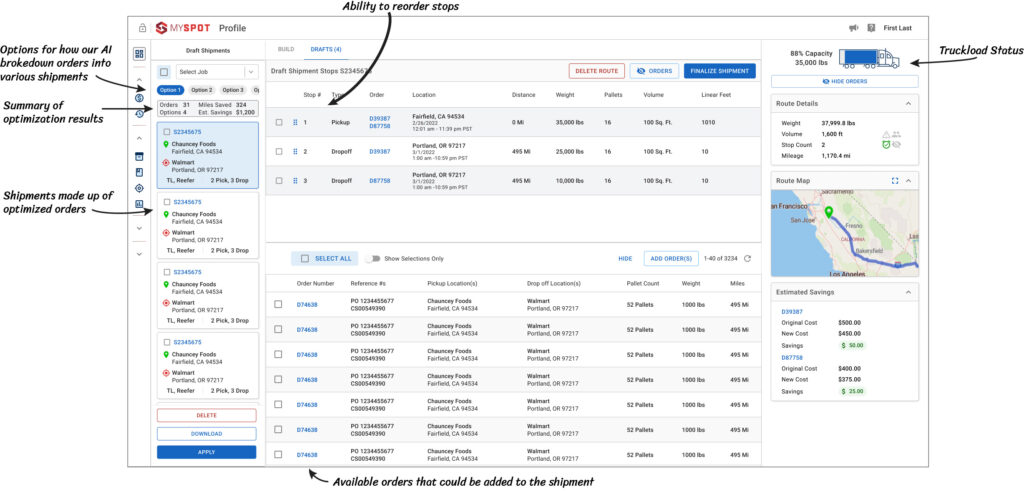

On the left hand side users have the option to select which optimization job they're currently running. Users are given different optimized options to choose from as well as a summary of the different options. Each shipment on the left is a draft. In the middle sections users can be reordered the stops of each draft shipment. If there's still room on the truck (as indicated by the truck icon on the right), users can bring up orders and add them to the current shipment before finalizing.

Optimization Workflow

The Outcome

Need some copy here

- - Favorable feedback from customers

- - Increase in savings from user base

- - Increase in time savings from user base